Following the Signs: Brand and the Bottom Line

Following the Signs: Brand and the Bottom Line

Attributing a financial value to brand equity and reputation can often feel like art rather than science, based on an opaque combination of proprietary analytics, extensive economic calculations and a healthy dose of “expert” opinion. However, while we can all agree on the fact that the brand is a crucial part of a business’ success or failure, even with some of the biggest names in the world, the most trusted brand valuations from the likes of Interbrand, Brandirectory and Forbes can vary dramaticallyi.

What’s in a Brand?

![]() Try as we might, we can never claim to own our company’s brand. It can be shaped, curated and managed, but the true value and challenge of the concept of brand is that it lives in the perceptions of external audiences; the customers, partners, staff and other communities.

Try as we might, we can never claim to own our company’s brand. It can be shaped, curated and managed, but the true value and challenge of the concept of brand is that it lives in the perceptions of external audiences; the customers, partners, staff and other communities.

![]() Brand visuals—the design language, colours, font and imagery—all serve to elicit an emotional response and offer a promise of an experience, level of service, set of values, etc. The foundation on which brands are built can change, with different ‘bricks’ growing or weakening in importance.

Brand visuals—the design language, colours, font and imagery—all serve to elicit an emotional response and offer a promise of an experience, level of service, set of values, etc. The foundation on which brands are built can change, with different ‘bricks’ growing or weakening in importance.

![]() In recent years, we’ve observed a marked shift in the level of importance of environmental and sustainability credentials in building strong brands with robust customer loyalty.

In recent years, we’ve observed a marked shift in the level of importance of environmental and sustainability credentials in building strong brands with robust customer loyalty.

![]() According to Trendwatchingii, consumers increasingly expect brands to act where governments and legislators won’t in order to make the world a better place. This has resulted in greater scrutiny of business practices as well as products and services.

According to Trendwatchingii, consumers increasingly expect brands to act where governments and legislators won’t in order to make the world a better place. This has resulted in greater scrutiny of business practices as well as products and services.

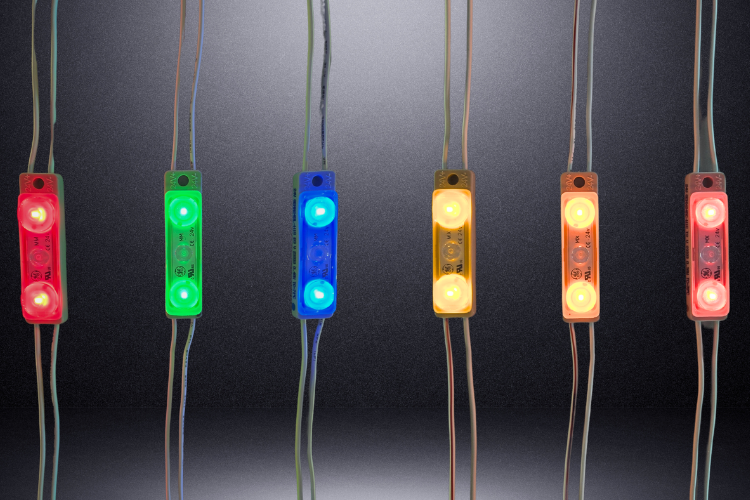

Since the early 1900s and the invention of neon, illuminated signage has been used to help brands stand out from the crowds through colour, design and scale. As times changed, technologies and markets may have evolved but the core function of illuminated signage remains constant: attracting attention and embodying the promise of the brand depicted, whether you’re looking at the huge logo on the side of a shopping centre or smaller informational signage inside.

What This Means for the Company Planning its Signage Project

Despite the boom in e-commerce and the well-publicised pressure on the high street, bricks-and-mortar businesses continue to dominate the economic landscape. Presenting their brand effectively has never been more important. However, businesses and building managers have to consider multiple—often competing—priorities when designing and developing their signage:

1. Ensuring that the singage depicts and represents the visual identity of the brand accurately and to the appropriate standard

This would include elements such as the accurate reproduction of the logo and correct Pantone colours used, as well as the sign reflecting the quality standards of the brand both up-close and from a distance. This is even more important where a franchising model exists as the HQ needs to set clear guidelines and quality standards to be followed by the franchisees to ensure brand consistency across the network.

2. Cost of manufacture and installation

Procurement managers working with the sign makers need to find the delicate balance between quality and cost. Whether they are investing in just one sign or rolling out a brand refresh to a national network of hundreds of outlets, signage can be a major investment for any business.

3. Running costs

Once installed, a sign might be difficult to access (e.g., on the side or roof of your building) so any equipment failure or on-site maintenance can be tricky, time consuming and expensive. Assuming no failures, the other major cost will be the ongoing electricity to illuminate the sign. This can be controlled on a timer to reduce power consumption in daylight hours, but the electricity will be a constant line on the CFO’s balance sheet so anything that can be done to reduce this cost to the business is worth considering.

4. Sustainability and environmental considerations

We’ve already seen how in today’s climate of awareness, stakeholders are calling on businesses to become more accountable for their impact on the environment and their local communities, taking a more proactive approach to reducing their carbon footprint. To this end, many businesses have signed up to the UN’s 2030 Sustainable Development Goals and follow the procurement processes and rules of BREEAM (BRE Environmental Assessment Method), a global accredited environmental rating scheme for buildings. It uses third-party certification of the assessment of an asset’s environmental, social and economic sustainability performance. BREEAM’s Green Guide specificationiii contains more than 1,500 specifications used in various types of buildings, with a ranking system graded from A+ to E, where A+ represents the best environmental performance/ lowest environmental impact and E, the worst.

With signage in particular, the cost (both financial and environmental) of disposal is an increasingly important factor considered at the procurement stage. Fewer components and less material going into landfill at the end of life will also allow a company to achieve a higher green rating and reduce the associated costs of disposal.

What This Means for the Sign Making Process

With the growing voice of the sustainability manager within modern business, it’s becoming easier to settle one of the age-old disagreements between the procurement team and facilities management, who tend to approach signage from two opposing points of view. Procurement teams typically seek to drive the best deal (e.g., lowest cost) for the sign purchase, without necessarily considering the other key factors such as the energy consumption, maintenance and disposal costs to the business. These would be the responsibility of facilities managers and the finance teams paying the utility bills each month.

Now, with the reputational and financial risks associated with neglecting their sustainability goals, businesses are prioritising long-term value over short-term savings, considering the total cost of ownership (financial and environmental) rather than the design and installation costs in isolation.

When planning an illuminated sign, the key considerations are:

| VOLUME OF MATERIALS AND LIGHTING MODULES USED | ENERGY EFFICIENCY | QUALITY AND UNIFORMITY OF LIGHT | LIFESPAN AND RELIABILITY OF THE TECHNOLOGY |

Selecting the Right Lighting Partner

With its toxic heavy metals and poor energy efficiency (approximately, ten times more energy is needed compared with LEDs), neon has generally been relegated to being used by artists rather than signage engineers. LEDs are now the dominant light source for illuminated signs around the world, but it’s important to understand that not all LEDs are created equal. When selecting a lighting partner, there are a number of fundamental questions to answer.

Q: What LEDs should we use?

LEDs are tiny chips, manufactured in huge wafers that are then cut into the individual units. The position of the chipset on the wafer can significantly affect three important characteristics: forward voltage, colour and intensity of the light emitted. As the variation can be significant, as part of the manufacturing process, the chips with similar characteristics are grouped or “binned,” allowing lighting fixture manufacturers to select their LEDs according to price or particular specifications and quality standards.

As colour variance can be significant, lighting fixture manufacturers like Current mix different bins of LEDs to ensure colour uniformity and consistency within the fixtures.

Q: How long will they last?

The useful life of an LED module is determined by a number of factors:

- LEDs are designed to be driven at a specific current, or range of currents in order to meet the lifetime claimed by the manufacturer. If you use a higher current the LEDs will fail sooner; drive them at a lower current and the lifetime can be extended.

- LED manufacturers will provide projected lifetime guidance for the chips under different ambient temperatures such as 55°C, 85°C and 105°C. These are calculated under stable lab conditions and could vary in real-world applications.

- Environmental factors such as humidity or the exposure to salt or naturally occurring sulphur dioxide can also limit the lifespan of LEDs—particularly those without a lens or additional effective protection.

- The quality and consistency of the power supply is also critical to maximising the lifespan of the LEDs. Most LEDs run on either 12V or 24V DC power and any fluctuation above or below can be damaging.

When working with a lighting manufacturer, ask to see the L70 claim for the lighting modules. This is the number of burning hours claimed within specified operating conditions, after which you could reasonably expect to still have 70% of the initial light output remaining.

For example, a claim of L70 being 50,000 hours, should specify the maximum ambient temperature in which the LED module is operated.

Q: How will the light be distributed?

Uniformity of illumination is the goal of every sign maker and in order to achieve this in the most cost-effective and sustainable way, it’s important to ensure that no light is wasted from each and every module. By directing otherwise “wasted” light towards the sign face, a good optical system such as Current’s OptiLens™ technology will allow the sign maker to achieve uniform illumination with fewer lighting modules, resulting in lower power consumption, fewer points of failure during the sign’s lifetime and less in the landfill at end of life. With fewer modules to incorporate into the design, installation times will also be reduced.

As well as potentially cutting the number of lighting modules required for a project (often by as much as 33%), a lens can also offer additional protection for the LED against environmental conditions, physical damage and lumen degradation.

However, with uniformity of light as the goal, the design and layout of the LED modules becomes critical. By using an expert team of light designers to plan the layout of lighting modules within the sign, businesses can ensure that they have used the optimal mix of materials to ensure consistent, high-quality output without any waste.

Q: Is my power supply reliable?

When it comes to ranking components in order of importance, the power supply (driver) is at the top of the list and any bid to cut costs in this respect can often prove to be a false economy. After connectors, drivers are the primary source of system failures, generating more maintenance and repair expenses over the lifetime of the sign. As there is little to visually differentiate a high-quality driver from a low-quality product, the best way to compare suppliers is to request the rated lifetime of the driver under a set of parameters, usually ambient temperature of operation (Ta). A lifetime rating of 50,000 hours under a Ta of 60°C is far better than the same lifetime under a Ta of 50°C. If you were to operate the latter driver in a higher ambient temperature of 60°C, this would effectively halve the lifetime from 50,000 hours to 25,000 hours.

Also, make sure you are aware of the failure rate; the industry standard for this is 0.2% per 1,000 hours of operation so a lower percentage would indicate a higher quality, more reliable driver. Current’s Tetra® power supplies are designed and proven in tests to have a failure rate of 0.1% per 1,000 hours of operation. Finally, ask the supplier to confirm the warranty for the power supply as this will also give an indication of product quality.

Q: What proof is there to underpin the claims?

When it comes to reassuring the CFO, sustainability and procurement teams of the value of a lighting system, it’s easy to get lost in the figures claimed, making it more difficult to compare systems. An independent LM79 report removes much of this confusion. It provides a detailed overview of the light output, power consumption and beam distribution of the module tested. Many lighting module manufacturers do not commission this test, preferring to use their own internal testing data. However, by insisting on this report, businesses are able to evaluate suppliers on an even playing field and better identify areas of higher value and performance.

In addition to the LM79 report, a 6,000-hour burning test will give a realistic indication of a module’s performance over its lifetime. Some manufacturers can even provide colour shift data, which is another very important attribute to consider as any change in the colour of the light can degrade the overall visual impression of the sign, requiring additional maintenance or replacement earlier than planned on the company balance sheet.

Finally, seeing is believing so testing the proposed lighting and signage system in situ for at least a year can also provide an indication of what to expect and help the signage partners to identify and mitigate any unforeseen factors that might affect the performance of the final sign.

Seeing the Light: An Illustration

As we’ve mentioned, there are many factors that should be considered as part of the sign procurement process, and short-term cost-cutting can prove to be a longer-term burden. To illustrate this, we have created a fictional client, McDougal’s, which is looking to renew its illuminated signage across its network of 150 stores.

This example compares cost and associated carbon footprint of Current’s 12V and 24V productsiv using McDougal’s “M” and extrapolating the data for the rest of the letters.

This example compares cost and associated carbon footprint of Current’s 12V and 24V productsiv using McDougal’s “M” and extrapolating the data for the rest of the letters.

- Overall Letter Height: 400mm

- Stroke Width: 110mm

- Overall Return Depth: 85mm

- Effective Return Depth: 72mm

- Face Material: 3mm Opal Acrylic 050

- Internal Return Finish: Non-painted alum

The Current modules were selected and laid out to try and achieve:

The best uniformity possible

Using the lowest number of modules

Offering the lowest levels of power consumption

To deliver a satisfying brightness level

Sample Comparison Data: GE 24V vs. GE 12V

Using the above example data and assuming an operation of 12 hours per day, 365 days a year, with 15% driver energy loss and an electricity supply at £/€ 0.12 kW/h, we can extrapolate the following estimated costs and savings over a five-year span with the 150 new signs.

Cost and Savings Over a Five-Year Period

Based on the above illustration, by investing more upfront to use the GE 24V modules, the company will recover this cost in just over one year and then make significant energy savings across the five-year period of the 150 signs, enough to power 24 average homes for one full yearv. And while the financial savings are significant, this reduction in energy consumption also equates to a total saving of 61 tonnes CO2, improving McDougal’s sustainability performance and earning more green points in its BREEAM audit.

To learn more about Current’s approach to sustainable procurement, get in touch or check out this article: Addressing the climate change challenge with sustainable procurement

i “What is a brand really worth?”, Forbes, 12th August 2017, https://www.forbes.com/sites/ryanerskine/2017/08/12/what-is-a-brand-really-worth/#84eb01822991

ii “5 Trends for 2019”, Trendwatching, https://trendwatching.com/quarterly/2018-11/5-trends-2019/

iii https://www.bregroup.com/greenguide/page.jsp?id=2069

iv Please note that the prices quoted are for illustrative purposes only – please contact Current for a more accurate quotation for your individual project

v Defra, 14